The handheld alloy X-ray fluorescence (XRF) spectrometer is an essential tool for Positive Material Identification (PMI) in high-temperature and high-pressure industries such as boilers, containers, pipelines, and manufacturing. It enables reliable material identification in critical national defense and civilian projects, including steel smelting, non-ferrous metals, aerospace, weapon manufacturing, and submarine shipbuilding. In engineering fields like petrochemical refining, fine chemicals, p

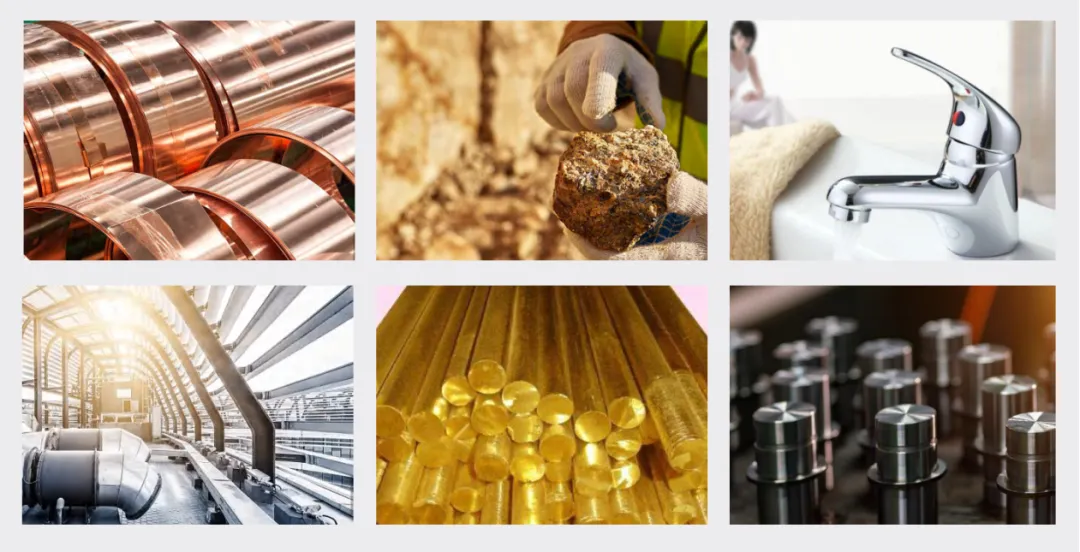

The handheld alloy X-ray fluorescence (XRF) spectrometer is an essential tool for Positive Material Identification (PMI) in high-temperature and high-pressure industries such as boilers, containers, pipelines, and manufacturing. It enables reliable material identification in critical national defense and civilian projects, including steel smelting, non-ferrous metals, aerospace, weapon manufacturing, and submarine shipbuilding. In engineering fields like petrochemical refining, fine chemicals, pharmaceuticals, power plants, and aerospace construction, the XRF spectrometer ensures material compliance during equipment and material acceptance to meet engineering standards. Additionally, it is a powerful instrument for identifying metals in the recycling and reuse of scrap metal.

| Specification | Details |

| X-ray Source | 45kV/200μA - Molybdenum target, fine focus, and high-performance X-ray tube |

| Detector | Si-PIN detector (for QA200) / SDD detector (for QA300) |

| Display | 1, high-resolution industrial touch screen > 5 inches, 2, resolution 1080*720 |

| Analysis Range | Sulfur (S) to Uranium (U) / Molybdenum (Mo) to Uranium (U) |

| Data Output | 4G, wireless connection, Wi-Fi, Bluetooth |

| Security Protection | Password protection |

| Data Input | Touch screen, keyboard |

| Battery | Rechargeable lithium battery, equipped with 6800mAh battery; voltage: 72V; continuous operation for up to 8 hours |

| Standard Configuration | Waterproof and dustproof protective case, Testing software for equipment, PC terminal, and handheld terminal |

| Compliance | CE, RoHS certified |

Widely used in quality control, material classification, alloy identification, safety assurance, and accident investigation, it facilitates on-site alloy grade identification and rapid metal composition analysis, addressing the fundamental challenge of raw material analysis in industrial processes. The handheld alloy analyzer incorporates cutting-edge research innovations, making it a reliable tool for identifying metal materials in production. Users can also customize the system according to their specific needs, creating a personalized analysis solution.

Handheld Alloy X-ray Fluorescence (XRF) Spectrometer QA200/300

Benchtop X-ray Fluorescence (XRF) Spectrometer QSEDX100A/100B

RoHS Compliance X-ray Fluorescence (XRF) Spectrometer QSRoHS-200/300

Coating and Plating Thickness X-ray Fluorescence (XRF) Spectrometer QTC200S/300/300S

QVA200 Vacuum Type X-ray Fluorescence (XRF) Spectrometer (Capable of Detecting Light Elements)